|  |

|  |  |

|

|

Hulls A hull is a hull is a hull?

WRONG! WRONG! WRONG!

All hulls are not the same! They are constructed differently from manufacture to manufacture as well as different types from one manufacture. A Win. AA is not the same as a Win. Dove And Quail. The AA is a one-piece Compression Formed (CF) hull, the Dove and Quail is a four-piece Poly Formed (PF) hull. Ballistics are completely different just as the ballistics for different brands vary. What works in Federal may not in Remington, they may be similar but not exact. The only safe way is to follow a recipe exactly! Be sure you identify hulls correctly; some look a lot alike but are different. Winchester CF are smooth, red, have an integral plastic basewad, tapered internally, low brass head on target hulls and brass plated steel head on high and low brass field loads, and an 8-point crimp. They are sold under the names A-A, A-A Handicap, Upland, Super Pigeon, Super-X, Super X-X. The PF are ribbed, red or black, a rolled paper basewad or plastic basewad, some have low brass, others brass plated steel head. These are sold as Dove and Quail, Rabbit and Squirrel, and Pheasant, among others.

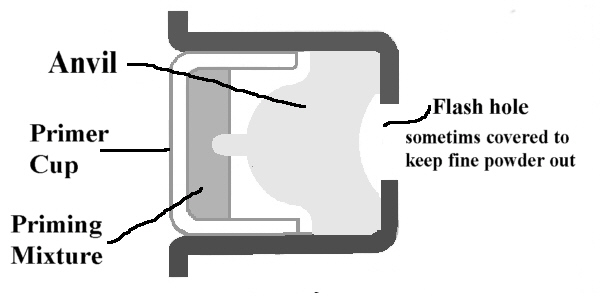

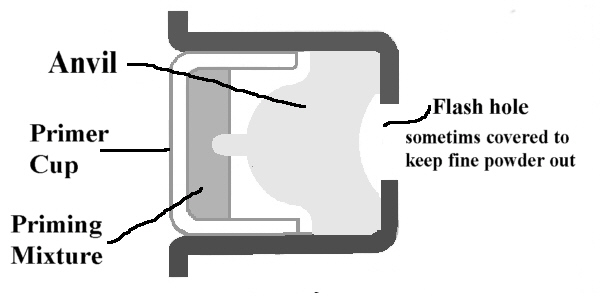

Primers

Several different size primers have been made over the years. The old brass shotshells had a primer pocket identical the ones used for rifle or handguns. This style took a primer very similar to ones used for metallic cases. Remington and Peters, at one time used a smaller primer than Winchester and Federal. This obsolete size was called a 57 or 157, or simply a Remington size. Today however, all U.S. shells and most foreign made take the standard size 209.

All modern shotshell primers despite looking alike develop considerably different ballistics with specific components.

A lot of reloaders think one primer is much the same as another. This misconception is because some retailers only stock one or two brands.

ALL SHOTSHELL PRIMERS ARE DIFFERENT!

There are 2 exceptions to the rule;

a. The CCI 109 and 209 are ballisiticaly the same, the difference is the 109 is nickel plated

b. The discontinued Rem 97 which delivers ballistics equal the Rem. 209P

AT NO TIME SHOULD ANY PRIMER BE SUBSTITUTED FOR ANY OTHER PRIMER.

Shotshell primers must be seated flush with or slightly lower than the head case. A primer not seated flush can cause chambering/feeding problems. It can also, under certain circumstances, be ignited and cause personal injury, property damage or DEATH.

Never attempt to decap a live primer. THIS COULD BE EXPLOSIVE!

If a live primer needs to be removed, Fire it in a shotgun, pointed in a safe direction. Firing only primers in a shotgun leaves a good bit of residue, which should be cleaned away before using.

Of all the reloading components, Primers are the touchiest, and must be handled with respect and care. Any detonation of a large quantity of primers can be extremely dangerous.

As packaged by the manufacture, primers are quite safe to handle. DO NOT transfer them to other containers such as a glass jar; if they were to fall on the floor or be knocked over they could become lethal.

Care should be exercised when using an automatic primer feed. Should one become stuck you should disassemble the feeder carefully. Do not bang or strike it as this could cause a chain reaction with any that are in the tube. Be sure to keep your priming system free of dust.

Remember to follow the recipe EXACTALY!!!

Powders The modern powder of today is neither smokeless nor powder. Gunpowder by defininition is an explosive. What we have today is actually a propellant and in comparison to black powder it is smokeless, but a little thin white puff is visible.

There are three types;

Ball or spherical

Flake

Tubular or extruded

Powders that use nitrocellulose as an energy source are called single base, when nitroglycerine is added, for extra energy content it becomes a double base.

Many powders look alike but their burning rates are different. If a question of identity arises, the powder should be discarded. There is but one thing to do with canisters that are unlabeled or you cannot read them- Discard them.

Powder should be kept in its original containers, it should not be transferred to glass or plastic jars as light will speed up deterioration, also should there be a fire the original containers are designed to split or push the cap off so the pressure dose not build to dangerous levels. Ignited powder will burn until it is consumed.

I use mainly one powder and buy it in bulk, then transfer it to smaller containers of the exact same brand and type. I store my powder in a metal gun cabinet that has two separate compartments and doors. I have added vent holes to the bottom top and two sides so gasses can escape if there is a fire.

There are more than a hundred propellants currently available. A large number are designed specifically for shotshells. There are also many handgun powders that can be used.

It can be confusing, I was! I studied and researched, researched and studied and was going Bonzo as well as driving my wife insane, by the way I succeeded. One day I was discussing my dilemma with a friend and he suggested a load to try, I did and it worked great. I tried others, and still do, but I keep coming back to Old Faithful,

18 grains RedDot, 1 1/8 0z. shot, Claybuster wad, win 209 primer and A-A hulls.

I am not saying that you should use this load, as what works in one gun may not in another, but a lot of other shooters I know swear by it.

Try different loads, sooner or later you will find one that works for your particular application. Remember, if you are trying to duplicate a favorite target or hunting load, all the info is on the manufacturers box.

As you gain experience you will become more familiar with different powders and their quirks.

Fast burning powders are best for light field and target loads, while slow burning powders for heavier loads. Generally fast burning powders are cleaner burning, which is something to consider. I personally enjoy spending 4, 5 or 6 hours at the shooting range, but do not relish the idea of coming home only to spend 2-3 hours cleaning my gun. Slow burning powders are usually dirtier.

|

|

|  |

|  |  |

|  |

|  |  |

|

|

Wad Columns The main purposes of the wad

1. Provide a seal, when the powder is ignited, to form the pressure to push the payload out the barrel

2. Protect the shot from the initial thrust of the burning powder, to prevent as much shot deformation as possible

3. Keep the shot away from the barrel to also aid in shot deformation prevention

4. Keep lead build up almost non-existant

5. Aid in better patterns

Substitution of any component(s) in a recipe can result in dangerously high pressures. The wad column is no different. Actually the improper use of wads can move pressure in either direction. The pressure can go so high as to cause bodily injury and or equipment damage. To do so shows a lack of respect for you, your equipment, or anyone else who might be present when the ammo is discharged.

As you research different manuals for the load you want to duplicate, you might notice that some list wad seating pressures. Although this is important, it is not so much as some make it seem. The only pressure you need, is to seat the wad firmly against the powder, with out any air pockets between the two. There are times more pressure is needed to compress the load to fit in the hull.

How much pressure is needed is up to you. A hull with tapered wall will require more than one with straight walls. Changes in shot size often require a change in pressure, a charge of # 6 shot may need more pressure than an equal weight charge of # 9s, simply because it takes up more room.

To confirm how much is needed, just make up a sample load after you seat the wad with the minimum pressure you feel is needed, (about 20 lbs.), but before you charge the shot, cut the side of the hull and make sure the wad is properly bottomed out. If there are air pockets between the wad and powder, more pressure is needed. You may need to go as high as 100 lbs.

Shot There are a number of types of shot, Lead, Steel, Bismuth, etc. Since I only reload with lead I know very little if any about the others.

In the lead category, there are three basic grades, Soft (drop shot), Hard (chilled or field), X-Hard (magnum or premium).

Soft shot is made of pure or nearly pure lead. It has the greatest density and as a result has the fewest number of pellets in a given shot charge weight compared to harder but less dense grades. It also deforms easier, with the initial thrust, and going through the forcing cones, barrel, and choke, many pellets are damaged. After they leave the barrel they meet a lot of air resistance that causes them to fly erratically, this results in a pattern with less density, they go all over the place. At short range this could help due to the wider pattern. Soft shot has the advantage when it comes to cost, its the cheapest.

Hard shot has an alloy added; usually its Antimony, 0.5 2.0 %. This is what makes it harder. It is also what is used in most factory field loads. There are more pellets in a given shot charge than soft shot as it is lighter. There is less deformation and patterns tighten up some. It works well in the short to medium range (10 30 yds.). It cost a little more but is good for practice.

X-Hard shot has more antimony, 3 6 %. This means even less deformation, which gives denser patterns. It is used in factory premium hunting and all top- quality target loads. It works well in the medium to long range. It cost more, but for better patterns, its worth it

|

|

|  |

|  |  |

|

Crimps Although the crimp is not a component, per-say, it is very vital to over-all performance.

After everything else has been assembled, you must have a good crimp, as it performs several important functions. It seals out dirt, moisture and keeps the shot from leaking out of the hull. It also helps confine powder gasses to ensure proper combustion. With plastic hulls, the quality of and resistance from the crimp is essential to proper combustion. Before the crimp opens there is a split second when the powder begins to burn well, the gas seal of the wad swells and the cushioning section of the wad collapses and moves forward compressing the shot against the crimp, then the crimp opens. With out a good crimp you cant have top- quality reloads. Anything less will reduce performance and or cause other problems. The powder needs to be confined for proper ignition. If it is not confined properly it can result in muzzle flash, light recoil, little velocity and an off- note report. If any of these happen you should check your barrel for obstructions. It is possible that the wad did not exit the barrel, if so, and you fire another round, it could be very hazardous to your health!!! Worn and or weakened crimp problems are compounded in cold weather. A good solid crimp is essential for cold weather performance. A firm crimp is needed when loading light loads, as it resist movement of the wad so pressure can build correctly.

Crimps come in two types, 6 and 8 point. For best results use the same as the original. Its really difficult to change one anyway.

The mouth (crimp area) of the hull becomes worn and weakened from repeated reloading and firing. Cracks will appear; it wont hold the proper shape etc. Inspect this area very closely, if you find any of these conditions throw the hull out. If the mouth is weakened the initial energy can push a light load forward before optimum pressure can build causing erratic performance and possibly an obstruction in the barrel.

Everyone who reloads is guilty of trying to get just one more reload from them, DONT, frustration is the only thing you will get, as it always happens at the most inopportune time.

Most factory 8-point crimps are skived (thinned and tapered) and usually easy to crimp. The skiving cost extra at production time and is not usually done to promo loads.

Variations in crimps can happen in same brand and type of hull. When a reloader buys, saves or scrounges from different sources, and mixes them together, variances can occur. For example 12 ga. Compression formed hulls (Super-X, Super Pigeon, Upland, A-A) are essentially the same, there can be slight volumetric differences however, but not critical, but the finished crimps can be different. Shotshell makers have been trying to standardize hulls in their production. One piece plastic hulls with a metal head for now anyway.

DISCLIAMER

CAUTION:

This web site is NOT designed to be a reloading guide. DO NOT attempt to reload until you have received competent instructions or have read and understand a reloading manual |